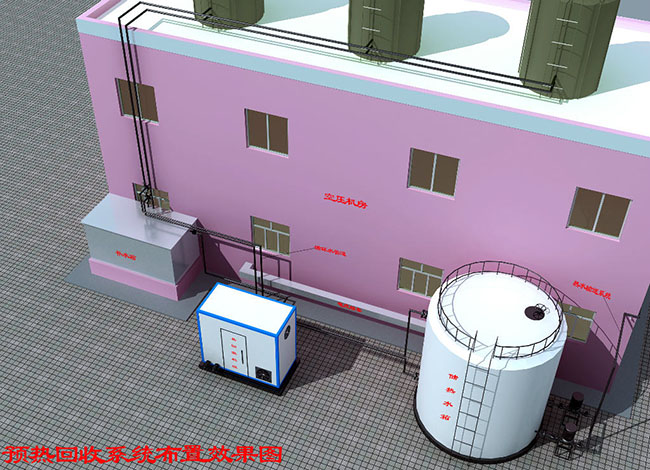

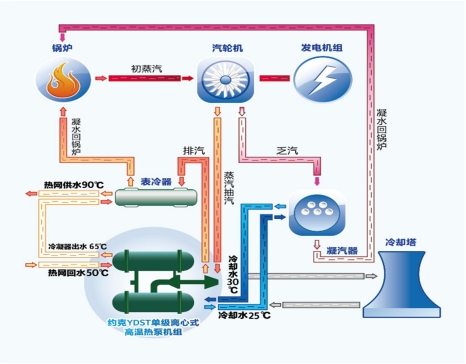

Using the technology of high efficient recovery emission of waste heat resources1, the technical ideasAccording to the emission of waste heat resources in the current system, the process route is generated based, the variation range of quantity of waste heat resources and parameters, through the waste heat resources survey system combined with the process of the system, according to emission steam priority back to the reuse of system, reduce the direct emission quantity, and then the minimum emission of steam to rational use principle, the realization of cascade utilization of waste heat resources, to improve the economic benefits of waste heat utilization ratio and system. Through the waste heat recovery, combined with the actual load and power equipment configuration technology of network system, can be used to drive the load (such as a water pump, fan), power, refrigeration (air conditioning equipment, heating or cooling use) (such as heating, desalted water deaeration preheating media, etc.).

2, the technical advantages

2, the technical advantagesA, using WHPN simulation software analysis, starting from the energy balance system, do a good job of cascade utilization of energy, reduce the emission quantity of waste heat resources, improve the economic system;

B, according to the system energy requirements, complete series of products, superior performance, flexible and provides a variety of use, including power generation, heating, refrigeration, drive;

C, a wide range of applications, can be applied to any high temperature liquid, saturated steam, low pressure steam, high temperature flue gas, superheated steam etc..

3, partial matching product features1), screw expansion of power unit

A, a heat source to adapt to a wide range of heat source, no high requirement of superheated steam, saturated steam, hot water, steam water mixture, high temperature flue gas, other heat body can use, is the use of pure waste heat.

B, variable condition superior ability in a wide range of heat source load and parameters (range from 20%-120%) fluctuation, can be stable, efficient operation.

C, low maintenance cost and belongs to the machine for ten years without major overhaul, repair and maintenance and operation are simple and convenient, for the original system does not produce interference effects.

D, the isentropic efficiency is high: more than 85% of isentropic efficiency of expander used to measure host thermodynamic degree of perfection, the isentropic efficiency is high, the energy conversion efficiency is high, the 1t/h 5kgf the following elution steam saturated steam through optimization design, net generating capacity of up to 105kW.

E project implementation units, convenient integration design, at the same time according to site requirements split installation, construction and movement is very simple.Unit

F, convenient operation and management unit start-up and load has the advantages of simple operation, can realize unmanned.

2) steam turbine units

A, a well-known domestic manufacturers to provide excellent performance, high efficiency, in;

B, wide scope of application, the lowest for the steam parameters of 0.25MPa (g) can meet the requirements of saturated steam;

C, according to the custom releasing steam parameters after optimization of the system, can be suitable for different occasions and steam parameters, in the zone of high efficiency operation;

D, advanced operation control system, equipment safety and stability;

4, the scope of applicationWidely used in iron and steel metallurgy, petrochemical, biochemical pharmacy, thermoelectric, and other industrial and mining enterprises, for superheated steam, saturated steam, hot water, steam water mixture, high temperature flue gas, other hot fluid recycle.

Steam network optimization technology

1, the technical ideas

In accordance with the ladder for energy, reduce pipe damage, the principle of recycling, focusing on the overall system optimization.

First use technique parameter acquisition proprietary standards and computer simulation, by detecting the current review system operating conditions, with the actual parameter calibration steam consumption of steam equipment, accurate judgement system of heat loss of specific reasons (divided into 7 big classes), and put forward the best solution for energy saving optimize system optimal feasibility through the analysis of network balance.

And then through the system optimization, transformation, from the source to reduce the amount of steam used, and by adding the efficient recovery device to maximize the recovery of waste heat utilization of bleeding, achieve administer thoroughly, achieve the best energy saving effect.

2, the technical advantages

A, with the system research, strict testing standards, for the system to provide complete and accurate data analysis and diagnosis;

B, with steady state simulation and optimization of advanced large-scale process simulation system, analysis of the various aspects of running the state, can provide accurate results for system analysis;

C, strictly follow the system to maximize the energy cascade utilization principle, energy saving efficiency and the overall economy is greatly improved;

D, the energy saving products matching complete, excellent performance;

E, the average saving steam energy consumption by more than 15%.

3, partial matching product features

1) high steam parameters of steam energy utilization efficiency of the control device

High steam parameters of heat energy utilization efficiency of the control device is used for precise control of steam equipment inlet steam parameters, improve the heat transfer performance, fully using steam latent heat, achieving the purpose of saving energy. The device is installed in the steam consumption of imported equipment for pipeline, including temperature sensor, precise control of the pressure sensor and the temperature reducing execution mechanism and an electrical control box. Through the determination of the actual temperature and the corresponding saturation temperature under the pressure of the comparison, the consumption will import temperature steam equipment control in accordance with the optimum superheat corresponding saturation temperature.

2) high performance hydrophobic valve

A, the body strong, simple structure, light weight, large range of operating pressure.

B, intermittent blowdown drainage and quickly close close, ensure no leakage. Do water drainage, heating equipment can achieve the best efficiency

C, an advanced design, the internal structure of stainless steel, ensure the hydrophobic has good resistance to corrosion and wear resistance, long service life.

D, convenient installation can choose thread, flange and welding connection mode.

E, provide various installation methods, can work in any position.

4, the scope of application

Widely used in iron and steel metallurgy, petrochemical, biochemical pharmacy, printing and dyeing, thermal power, and other industrial and mining enterprises, energy saving and energy saving design optimization of the steam network, steam equipment, high temperature heat source recovery system.