Technology & Product Profile

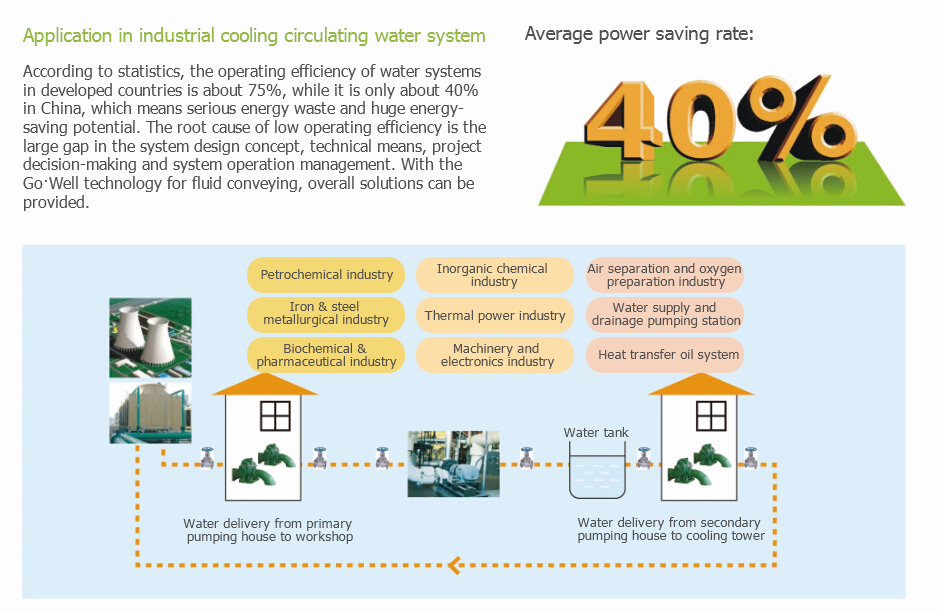

Go·Well Technology for Fluid ConveyingAiming to solve the problems of low efficiency and high energy consumption of fluid conveying systems of public buildings, municipalities and industrial and mining enterprises at present, especially industrial cooling circulating water systems, ECOWELL developed the advanced systematic optimization and energy conservation solution.

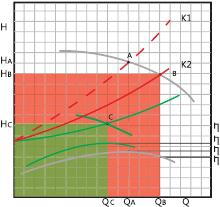

Technical conceptsGuided by the principles of the best operating conditions and most reasonable energy consumption, the company focuses on the overall system optimization from the most fundamental three elements (pipeline impedance, operating efficiency and conveyed flow) affecting the energy consumption of the water pump.

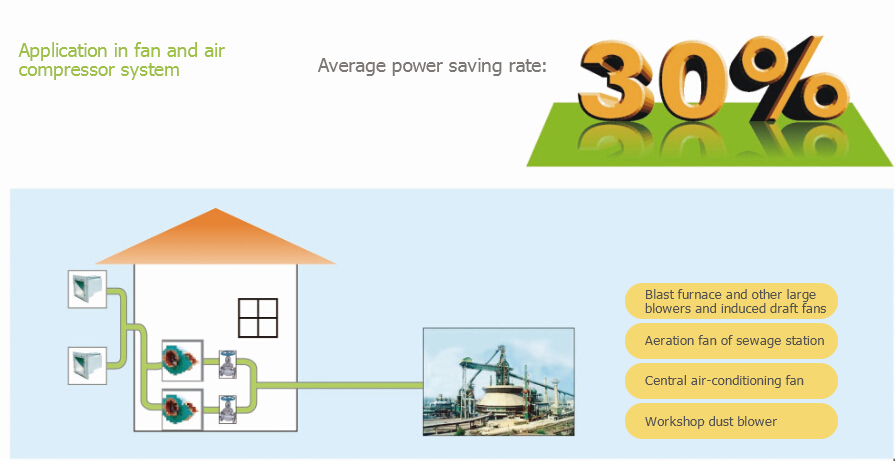

At first, using the special parameter collection standards, computer simulation and other technical means, accurately judge various causes of high energy consumption (13 categories in total) by testing and rechecking the current operating conditions of the system, and put forward the best solution of system optimization and energy consumption. Then comprehensively improve the system efficiency of energy utilization by configuration optimization means such as modification of unfavorable factors of the pipeline network, overcoming of the bottleneck of heat exchange, optimization of hydraulic balance and parameter settings and customization of high-efficiency energy-saving pumps. For systems subject to large load changes, install the variable-flow control system to realize energy conservation based on the operating conditions and further improve the operating efficiency. The company focuses on overall energy conservation for the best energy-saving effects. The Go·Well Technology for fluid conveying is also applicable to optimization and energy conservation of fan and air compressor systems.

Core technologies1) Data collection standards

2) System diagnosis and analysis technology

3) System optimization and transformation technology

4) System supporting products:KW(S) series high-efficiency energy-saving pump

KW series hydraulic balance adjustment device

ECOWELL circulating water online monitoring and energy management

system

ECOWELL variable-frequency energy conservation control system

ECOWELL high-efficiency cooling tower spraying device

German quantum cleaner

Hydraulically driven fan unit

Carbon composite wing-type energy-saving fan blade

Technical advantages

1) Accurate high energy consumption detection and diagnosis capabilities to accurately analyze the energy-saving potential and measure energy-saving benefits.

2) Overall energy conservation based on system optimization to achieve significant effects. The average power-saving rate of circulating water systems is no less than 40%.

3) Complete energy-saving products with excellent performance.

4) Use of diagnostic analysis software to provide quantified energy conservation design schemes for new or expanded projects to achieve “energy conservation in advance”.

Characteristics of some supporting products

ECOWELL ECOWELL energy-saving pump

1) Use the tertiary circulation technology, and analyze and design the flow velocity field based on the CFD computational fluid dynamics to design the high-efficiency energy-saving pump which is the most applicable to the requirements of the operating point.

2) The wide scope of high efficiency and performance is more applicable to operation under changing conditions caused by load changes.

3) With the advanced hydraulic model and high machining precision, the pump efficiency is more than 10% higher than that of the conventional pump.

4) With high anti-cavitation ability, meet the NPSH requirements of field devices.

5) The mechanical performance is excellent. Castings are molded and cast with resin sand. All parts are machined through CAM.

Dual-power hydraulic drive type cooling tower fan energy-saving device

1) The cooling tower fan is driven by the power of the turbine and motor in a complementary manner, and 100% of return water energy can be recycled, thereby ensuring normal cooling of the cooling tower under the maximum load and making system operation safer and stabler.

2) The high-efficiency turbine is customized according to the discharge parameters of the cooling tower, with the advanced hydraulic model and wide scope of high efficiency to better adapt to operation under various conditions caused by load changes. The operating efficiency is more than 10% higher than that of the conventional turbine.

3) The multi-tooth double-line contact is used for the transmission, reducing the pressure on the toothed surface and increasing the bearing capacity. The speed ratio can be customized flexibly to meet different parameter requirements.

4) Characteristics of the electrical control system:

a. The control method and operation mode of the original motor control cabinet are not changed.

b. Automatic operation can be done based on load changes by switching the manual/automatic mode according to the temperature of circulating water.

c. Docking with the DCS system can be done for centralized control according to system needs.

Dual-power hydraulic drive type cooling tower fan energy-saving device

1) The cooling tower fan is driven by the power of the turbine and motor in a complementary manner, and 100% of return water energy can be recycled, thereby ensuring normal cooling of the cooling tower under the maximum load and making system operation safer and stabler.

2) The high-efficiency turbine is customized according to the discharge parameters of the cooling tower, with the advanced hydraulic model and wide scope of high efficiency to better adapt to operation under various conditions caused by load changes. The operating efficiency is more than 10% higher than that of the conventional turbine.

3) The multi-tooth double-line contact is used for the transmission, reducing the pressure on the toothed surface and increasing the bearing capacity. The speed ratio can be customized flexibly to meet different parameter requirements.

4) Characteristics of the electrical control system:

a. The control method and operation mode of the original motor control cabinet are not changed.

b. Automatic operation can be done based on load changes by switching the manual/automatic mode according to the temperature of circulating water.

c. Docking with the DCS system can be done for centralized control according to system needs.

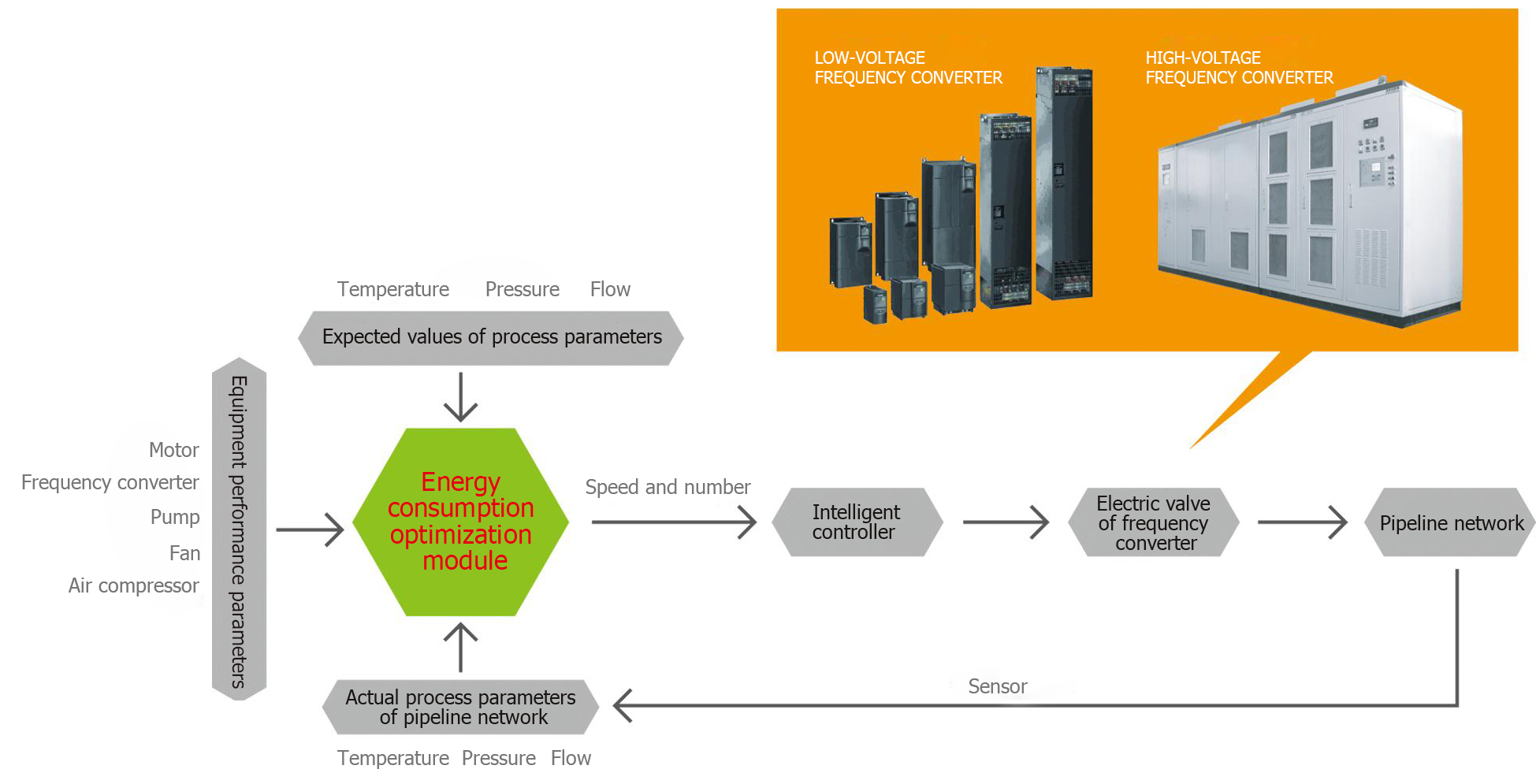

Characteristics of ECOWELL Variable-frequency Energy Conservation Control System

Control Principle

Use the closed-loop intelligent control technology for automatically optimization by real-time sampling process parameters and comparing with target values to find the operation configuration and speed control strategy with the lowest power consumption, control the speed of the pump, fan and air compressor and thus achieve the best energy-saving effects.

Characteristics of Control System

1) Automatic optimization to find the operation configuration and speed control strategy with the lowest power consumption.

2) Intelligent automatic control and prompt, smooth and accurate adjustment.

3) Automatic fault diagnosis and over-current, over-voltage, under-voltage, overload and short-circuit protection.

4) Real-time measurement of operating power, accumulation of power and operating time and accurate control of energy consumption and saved power.

5) Friendly human-computer interface and direct touch operation.

6) Provide the RS485 or Ethernet communications interface and support MPI, PROFIBUS and other protocols to realize data sharing.

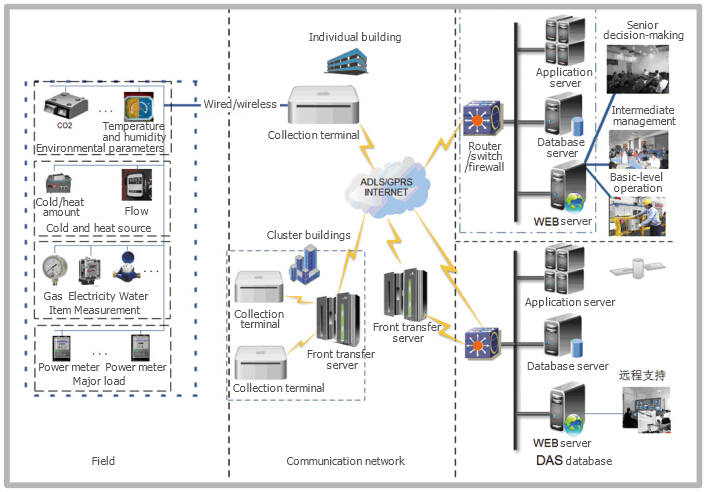

ECOWELL Circulating Water Online Monitoring and Energy Management System

ECOWELL is the only one company which has successfully developed the circulating water online monitoring and energy management system with independent intellectual property rights. The cores are the mathematical model for system operation optimization, system architecture and wireless data transmission, which solves the problems of fine energy conservation and intelligent management.

1) Accurate and real-time monitoring of main parameters of the whole circulating water system, including pumping stations, header pipes, unit branches and major water points.

2) Measurement, control and evaluation of the reasonableness of the water amount of main heat exchangers on each unit and terminal of the process side to ensure the reasonable water consumption.

3) Provide strategies for efficient operation of pumping stations in various modes according to the on-demand supply principle.

4) Real-time measurement of operating power, accumulation of power and operating time and accurate control of energy consumption and saved power.

5) Accurate water amount statistics, water energy consumption indicators and cost assessment data of pumping stations and main hydraulic units.

6) Real-time tracking and recording of maintenance to ensure prompt maintenance of each pump.

7) Online monitoring of operating conditions of each pump and prompt alarm to ensure the pump operating safety.

8) Friendly human-computer interface and direct touch operation.

German Quantum Cleaner

1) Use the special molecule (lattice) vibration wave for erosion resistance, descaling, disinfection and algae removal.

2) Prolong the service life of the pipeline network and heat exchange equipment, obviously solve the problem of poor heat exchange effects caused by scaling or microbial growth in heat exchange equipment, and improve the water quality.

3) Use the ring-type structure which can be directly sleeved outside the water pipe and subject to online construction.

Application scope

Widely applied in the energy-saving technology improvement and optimization design of the industrial cooling circulating water system, heating and air-conditioning circulating water system, water supply and drainage pumping station, heat transfer oil system, fan system and air compressor system.

The industrial cooling circulating water system is mainly distributed in:

1) Petrochemical industry (pyrolysis, gasification, separation, synthesis, polymerization and other heat exchange processes, involving 8 basic raw materials, 14 basic organic raw materials and 3 major synthetic materials);

2) Inorganic chemical industry (sulfuric acid, chlor-alkali chemicals, etc.);

3) Synthetic ammonia industry;

4) Coke, methanol and coal chemical industry;

5) Biochemical pharmaceutical industry (heat exchange in the fermentation process);

6) Iron and steel metallurgical industry (steel, electrolytic aluminum, copper);

7) Thermal power industry;

8) Machinery & electronics;

9) Building material industry (float glass process).

• Energy consumption indicator of air-conditioning circulating water designed with Go·Well technology: ≤26W/kW

• Energy consumption indicator of air-conditioning circulating water of Japanese green hotel: ≤28.6W/kW

• Energy consumption indicator of domestic air-conditioning circulating water at present: 59-143W/kW

• The energy consumption indicator of the air-conditioning circulating water means the power consumption required for conveying of unit cold (heat) amount, in W/kW.