Fan energy-saving ways and SolutionsFan product varieties are divided into centrifugal compressor, axial flow compressor, centrifugal blower, roots blower, leaf blower type ventilation fan and axial-flow fan with seven types.

| Centrifugal Compressor | Centrifugal blower | Axial flow fan |

1. Problems exist in the use of the machine, the windThe fan has the following four problems in the process of use:

(1) fan improper selection. One is the air volume and pressure need layers of overweight. This phenomenon has technical problems, there is a man-made problem, also has the current design specification and other aspects of the problem. Such as some non professional personnel selection of fan when the lack of calculation, the lack of investigation and Analysis on hand, only rely on the existing sample. Some of the design supervisor conservative stability, calculation of air volume, air pressure is too large, ignore the economic analysis. More is poor design and installation quality of pipeline system, the maintenance management level

Low, difficult to consider many factors, it is difficult to design personnel; two is the wind pressure is too big or too small. Pressure will cause the actual choice of increasing air quantity, will cause the power increase, energy consumption increases, the initial investment is rising, the quality and to increase in size and a series of consequences; pressure too small will lead to lack of wind, can not meet the need of production. In addition, the motor is in low load operation, low efficiency.

(2) fan does not detect, no regulation or regulation is not perfect. A large part of the wind turbine in a non full load operation, if not timely necessary adjustment, will cause the fan motor, inefficient operation, waste of energy. Because the field of wind pressure, air volume needed is not clear enough, coupled with the lack of necessary regulation, even if the choice of high efficiency fan can also be of no avail, the so-called high efficiency fan inefficient operation.

(3) the wind machine pipe network layout is not reasonable.

(4) the low level of scientific management. There are quite a number of fan in the field is no management or exist in the management of state. Some fan long at a reasonable operating, some field staff just doesn't ask whether energy-saving and reliable operation. The actual production process does not need the fan, fan is still in constant speed operation etc.

2. the causes the fan power consumption

1, within the fan efficiency is low. All kinds of fans of domestic wind turbine industry production, most of the low efficiency of.

2, fan series type spectrum insufficiency. Because of the wind machine, especially the series type fan spectrum, the fan users in the catalog can't find suitable varieties and machine number, and was forced to use alternative models of the wind turbine, resulting in the multi power consumption.

3, the low efficiency of the fan device. One is the transmission mechanism of fan is relatively backward, such as V, etc. with the worm gear pair is also widely used in fan, so that the transmission efficiency of the fan is low; the two adjusting method is relatively backward, the majority still use the valve regulation. Because of the above reasons, although the fan most of the inner efficiency is high, but the device efficiency is not high.

4, fan actual working point deviates from the maximum efficiency operating point. Because of the designer to the pipe resistance calculation is not accurate, but worry about the calculation of pressure and flow can not meet the conditions needed, the choice of security margin over large, or there is no suitable performance specifications are optional and the fan of high-grade performance or high pressure area. The results, because the layers of overweight, rated air caused by the selection of fan is far more than the actual desired volume. Then the wind machine operator had no choice but to use the inserting plate or adjust the throttle valve to artificially increase the resistance, in order to reduce the volume, so as to meet the operating point. Due to the increase of the artificial resistance, resulting in low efficiency in the use of wind machines, leading to the waste of electric energy.

Supporting the motor capacity of 5, fan selection is too large. Because domestic motor specifications are difficult to fully meet the fan motor matching, selection of high-grade power ratings of the procurement, resulting in the big car Mara, reduced motor load rate, a waste of energy.

6, the pipeline system design unreasonable, increasing the pipe resistance, reduce the use efficiency of fan.

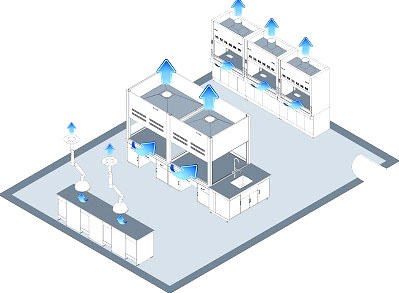

Closely related to network configuration and network layout of energy saving, good or bad, will directly affect the play of fan performance. On-site, network configuration is reasonable phenomenon is mainly manifested in the following aspects.

(1), extra fittings and flow in blast crisis. Network is a fan and pipeline system is directly connected with the pipe, wherein the pipe joint, elbow, three links are often redundant and valve; there are many unreasonable flow cross section in the air flow, such as a sudden expansion but narrow, suddenly shunt, direction change or sharp turns etc..

(2), air leakage. At the scene, the air leakage is not only pointless waste, is also a source of noise pollution. The leakage reasons, some technological defects caused by. In the usual pipe network, leakage occurred in the throttle valve (baffle), pipe connections and fan station itself.

(3), the fan inlet and outlet pipeline layout is not reasonable. Because the layout is not reasonable, factitious ground is caused flow distortion, affecting the capacity of fan.

A, inlet pipeline unreasonable mainly manifested in the following aspects.

The lack of necessary imports straight pipe section, or through divergent taper pipe is connected with the inlet.

The fan inlet and sharp lines directly connected.

The fan inlet and sudden contraction pipe is connected, or the air inlet box structure is not reasonable.

B, the fan outlet piping layout is not reasonable performance in:

The outlet of the blower is connected directly, 90 degree bend or reverse bending;

The outlet of the blower is directly connected with the branch pipe;

The outlet of the blower is directly connected with the sudden expansion pipe.

7, fan in use by inappropriate or inefficient regulation method, reduces the fan regulation efficiency.

8, poor management. Without strict, scientific shutdown regulations and measures, early or late boot shutdown will result in a waste of electricity.