(1) air compressor fleet control strategy module:

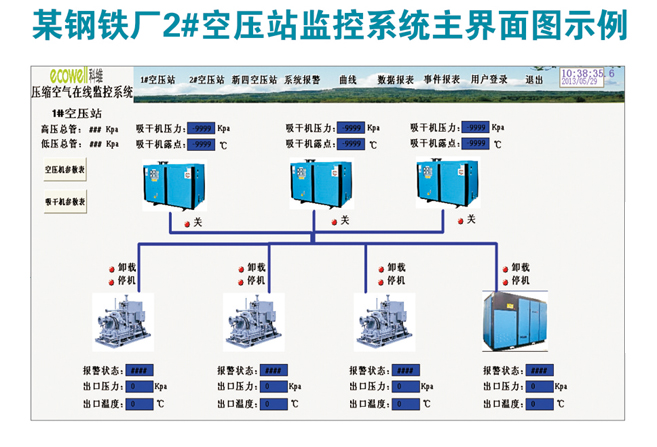

Air compressor fleet control strategy based on the actual situation of the system gas reasonable control air compressor operation quantity, balance the air compressor running time, optimization of air compressor operation mode.

(2) air compressor mechanic/inverter to run for a few days to control function module:

For the air compressor and frequency conversion device operation, alarm information for recording, storage, query, and generate reports.

(3) dryer spreading function modules:

According to the practical operation of air compressor system to open/associated control of drying machine, and the import and export valve open/close your dryer from spreading.

(4) network flow/pressure monitoring module:

Through the network of jet flow and pressure sensor installed in the system the main point of gas pressure in the gas pipe network, traffic, to call the police, flow, pressure abnormal points and record the gas problem, storage, and generate reports.

(5) the energy metering management module:

Voltage/current/power factor of monitoring equipment to monitor the parameters, such as display data curve, data tables, and to save the test data, the report summary, report forms printing.

(6) cooling water circulation monitoring module:

Hollow press operation according to the system of air compressor cooling water inlet/outlet valve on/off from spreading and water pump on/associated control scheme of recirculating cooling water system.

(7) equipment maintenance management module:

Real time recording equipment maintenance, according to each equipment parts maintenance cycle regularly remind field personnel for equipment maintenance.

ECOWELL compressed air online monitoring system of energy efficiency for conveying fluid, Go well, technology products, it through the air compressor, each unit branch and main gas stations, main points of online monitoring, timely feedback air compressor station throughput and energy consumption, process gas, and provide the control strategy according to the energy consumption, the optimal principle, ensure energy saving after the compressed air system is in a state of high efficiency, energy saving, trouble-free operation; System also provides a variety of reports and statistics for the compressed air flow, cost assessment and the electricity quantity measurement provides accurate data.

Computer control system is divided into equipment, monitoring layer and management layer, control layer four hierarchies, constitute a distributed network of industrial control system, including equipment layer is responsible for the physical signal into a digital or standard analog signal, control layer to complete the process of real-time monitoring and control on the spot, monitoring layer through the centralized management of the multiple control equipment, to complete the purpose of monitoring production operation process, management of production data management, statistic and query. Compressed air online monitoring system of energy efficiency is to be located in monitoring layer and part of the management function of the software, is responsible for the centralized management control layer, connected up management, is an important part of enterprise informatization.

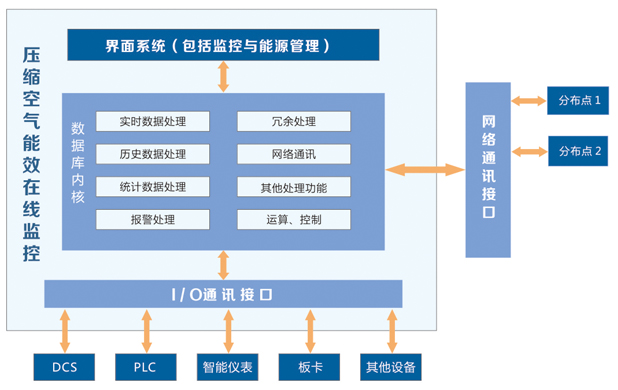

Compressed air online monitoring system of energy efficiency of architecture, as shown in the figure of the system software can be divided into three layers of structure: data acquisition, data processing layer and layer interface system. The underlying data acquisition layer, data acquisition layer is the system through the corresponding I/O communication interface from the scene of the DCS, PLC control, intelligent instruments, boards or other device to real-time data collection, and the real-time data in the system of real-time database, and at the same time, the system control information (instructions to control the field controller express execution. An intermediary for the data processing layer, the function of this layer includes: real-time data processing, historical data processing, statistical data processing, alarm processing, redundant processing as well as the operation and control of the internal data. Is the role of the middle layer up to collect real-time data to calculate data acquisition layer, statistical processing, processing good information data to the upper layer interface system for display and analysis. At the same time, the middle layer also accept the upper layer interface system of control signals transmitted to the lower level data acquisition layer. So the middle layer is the core of the system control part. Upper for interface system layer, the layer is the middle layer, according to the processed data information by monitoring interface, trend curve, the pie chart presented to the user, all kinds of report forms, such as intuitive accurate data information; At the same time in the monitor screen can be carried out on the field controller real-time operating control.

Ultrasonic leak detection instrument, pipe network leakage monitoring technology

A 2 mm holes, 7 bar (0.7 MPa) the pressure of the compressed air system, the cause of leakage is about 0.296 m3 / min, the compressed air consumption indicators according to the qualified standard of Gb/T16665-1996 standard. 0.112 Kw h/m3, equivalent to a loss of power of 2.0 degrees per hour, the year according to the 8000 hours running time, the power loss of up to 16000 degrees every year. If electricity calculated according to 0.65 yuan/degree, the year of the waste of more than 10000 yuan!

Usually the compressed air system leak point mainly in the following aspects:

1, the air compressor ontology includes condensate expeller leak, oil-water separator leakage point.

2, the post-processing stage includes condensate expeller leak, the gas pipe section of the connection of the dryer.

3, compressed air system air tank, pipe condensate ejector leak.

4, locations, such as the nozzle size is too big, and so on tool damage.

At the scene of the compressed air system

Operating power detection:

Visual display of three-phase electric equipment of voltage, current, power factor and equivalent input power, voltage measurement accuracy reached 0.2%, current measurement accuracy up to 0.5%.

Network traffic detection:

Direct measurement of mass flow rate and the standard flow, without pressure compensation.

Dew point pressure measurements:

Existing in the compressed air pipe too much water will cause: the abandonment of products, pneumatic components life shortened, actuator fault, pipeline corrosion, and the plan of production interruptions, etc., will bring immeasurable loss. By dew point measurement and control, able to timely discover and deal with problems in the process of compressed air drying and improve the efficiency of maintenance of compressed air system.

Pressure testing

Using diffusion silicon pressure sensor as a sensitive element, through the high precision of signal detection, linear amplification processing, comparison and logical operation process, and finally to isolation of different pressure value of monitoring the output control signal, through the graph output, visual display pipe network pressure fluctuations.

Temperature detection

Data recorder: can connect all kinds of sensor measurement tasks, such as flow rate, pressure, dew point, power, current, etc. Maximum 24 channels of input data at the same time, and through software for data analysis, in the form of charts and data output.

Measurement of air compressor system