Compressed air system is the most widely used in industrial field one of dynamic service source. In steel, metallurgy, chemical industry, building materials, textile, chemical fiber, automobile, ship, paper, packaging, food, medicine, military industry, such as navigation days have lei quantity in manufacturing applications. In most enterprises of compressed air energy consumption accounted for 10% of the total power consumption to 10%.

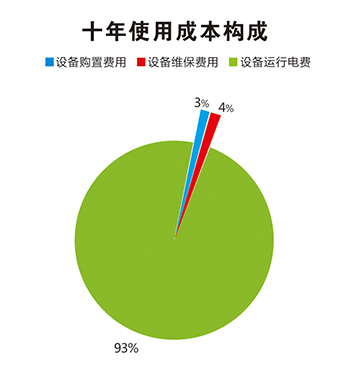

The cost of the compressed air system

For system throughout the life cycle, the air compressor running electricity is the main cost spending.

Example: the 250 kw air compressor, running 8000 hours a year, electricity price is 0.7 yuan, equipment service life of 10 years, for example,

Calculate fees are as follows:

Equipment purchase cost: 400000 yuan (the market mainstream brand air compressor and the person who purchase price)

Ten years equipment regular maintenance cost: 60000 = 600000 yuan/year by 10 years

Ten years operation electricity: 250 kw. H * 8000 H * 10 * 0.7 = RMB 14 million per year

Three charges together to: 15 million yuan

Pipe network layout and piping configuration is not reasonable, lead to energy loss

System leakage caused by pipeline transportation inefficiencies

, gas equipment at the end of the unreasonable use of waste energy

The compressed air system energy saving space

Covey company to solve these problems, at the end of the reasonable gas for the principle, with equipment operation of the best and most reasonable energy consumption as the goal, relying on proprietary parameter acquisition criteria and computer simulation technology, such as the current operation condition through the test, check system, accurate judgment caused by high energy consumption of a variety of reasons, put forward the system energy consumption is to optimize the best solution.

Covey compressed air system energy saving solutions

Improve equipment, application ECOWELL efficient air compressor can effect comparing

· application ECOWELL energy-saving drying machine to save energy consumption of drying part

, application ECOWELL online control system to improve equipment efficiency

Online application ECOWELL energy monitoring system, improve the efficiency of management

Application ECOWELL intelligent traffic controller improve the system's operation mode adjustment ability

, the application of ECOWELL heat recovery unit for air compressor waste heat recycling

System pipe network optimization and pressure adjustment

Gas equipment at the end of the pipeline leak monitoring and flow optimization

Covey compressed air system energy saving products

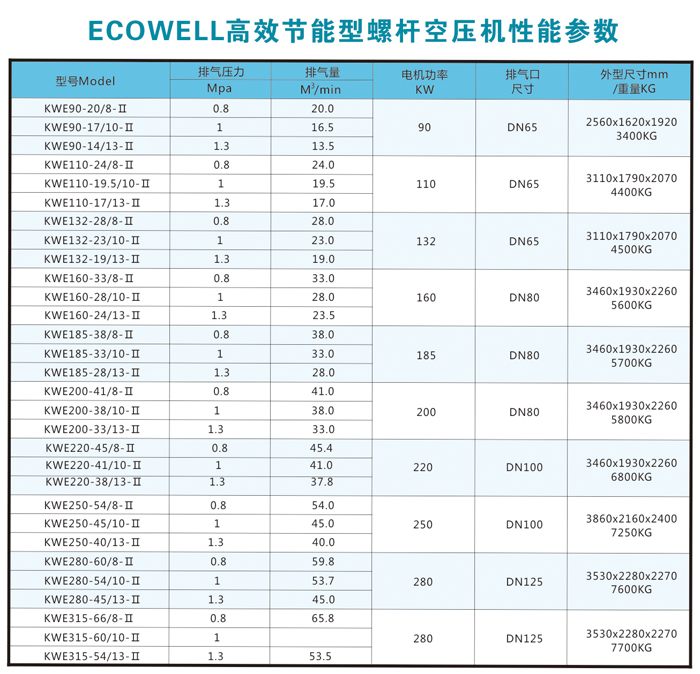

ECOWELL efficient screw air compressor

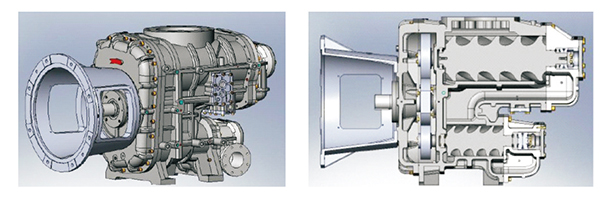

North American compressor institute of the latest scientific research achievements of application - Y3 screw type line, adopting two stage compression technology, entrust the international famous screw compressor manufacturer specialized in manufacturing. All series of products through the national certification of energy efficiency.

Product has the following features:

Reliable, high efficiency, energy saving

(1) isothermal type two stage compression screw host

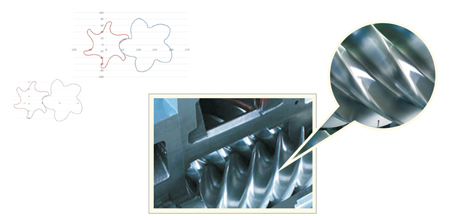

(2) Y3 new rotor type line, patent design

Advantages: lower compression ratio and reduce the bearing load

Each level due to low compression ratio, compression process and reduce the load of bearing, prolong the service life of bearing.

Advantage two, isothermal compression, reduce heat compression

Two stage compression efficiency is one of the reasons why the interstage coolant jet curtain design. To a level of compressed air spray mist cooling agent, can achieve unexpected air cooling effect. This compressed air into the secondary compression stage before, and reduces the temperature of the air, greatly saves energy needed to compress. And the use of coolant jet curtain can dispense the coolant in the middle.

Advantage three type line, unique design, primary and secondary rotors are running at optimal tip speed

This type of line design can obtain the best compression efficiency, over 20% of energy than a conventional screw host.

Advantage four, SKF roller bearing and angular contact bearing the joint design, by the angular contact bearings bearing axial force

This design can effectively ensure reliability and running stability of the rotor, the dynamic balancing experiments, rotor radial deviation less than 0.03 um.

Advantage five, using electronic fuel injection allocation system

The system automatically adapt to the environment temperature, the air, temperature of cooling water, the change of the flow and pressure, to ensure the temperature control in the compression of the host within a reasonable range of 80 ~ 100 ℃.

(3) using efficient high torque motor

Motor parts performance indicators:

Manufacturing standards: NEMA standard

Insulation class: F, class B temperature rise

Protection grade: IP54 / IP23

Rated speed: 1485/2980 RPM

With overload, open phase protection function

(4) vortex form efficient oil and gas separator, rapid separation, minimal pressure loss

Super efficient two stage to exhaust separation filter, oil and gas separator filter selects the permeability of the excellent and durable nano materials, the service life of up to 8000 hours, fold structure increased the filter area, little flow resistance; Can guarantee under the premise of exhaust efficiency against losses, make exhaust oil content is lower than 2 PPM.

(5) choose this type of bearings SKF overloading

Bearing for the rotor in the process of rotational loading (axial and radial force), guarantee of the gap between the screw rotor, thus bearing is important in the moving parts of screw host.

ECOWELL compressor with Swedish SKF company B - 10 e (overloaded wear-resisting bearings), design service life of 130000 hours.

Supporting air compressor host Yin and Yang of rotor inlet end USES the cylindrical bearings, exhaust end the use of the back-to-back angular contact bearings to withstand and/discharge when the axial and radial force.

(6) direct drive, gearless consumption loss, high transmission efficiency

Using high-performance KTI elastic coupling, effectively combines the advantages of belt and gear coupling, and overcome their disadvantages: high transmission efficiency, and motor drive ratio of 1:1, effectively protect the motor. Main features:

, vibration absorbing ability;

, torque is maximum;

, but the radial tear open outfit;

Less, the connecting bolt (10);

Low, assembly and to the requirements.

(7) the air-filled type inverter centrifugal fan

The correct cooling system design is a key to ensure the reliability of the compressor. ECOWELL compressor cooling fan adopts frequency conversion control, large flow design, according to the environmental temperature and exhaust temperature automatically adjust the motor speed, low power consumption, low noise, long service life.

(8) use of coolant for quality, long life, no carbon deposition, not glue

KERRY compressor for oil main performance indicators:

ISO viscosity classification: VG 32

Viscosity (40 ℃) : 32.2

Viscosity (100 ℃) : 5.61

Viscosity index (D2270) : 113

Density (15 ℃) : 0.8645 g/M3

Flash point: 257 ℃

57 ℃ pour point: -

Emulsification trend (D1401) : 40/40/0 (20 minutes)

Performance characteristics:

High stability, anti-oxidation, run up to 8000-10000 hours;

High security, high flash point 257 ℃;

Synthetic rubber compatibility, outstanding;

, the inherent high viscosity index, shear stability;

Weak, volatile;

Thermal conductivity, excellent;

, the hydrolysis stability of the high - gas and liquid separation effect is good;

, strong dirt and focal scale formation;

To dissolve the existing oil dirties, automatic cleaning the old compressor oil;

(9) with low noise design

Heavy duty design,

, straight driving, no gear noise

Large diameter rotor, low speed (1485 RPM)

, low speed, frequency centrifugal fan;

High efficiency in hot water cooler

Air intake muffler, shell; The compressor inlet noise elimination

Precision sheet metal outer shield

(8) use of coolant for quality, long life, no carbon deposition, not glue

KERRY compressor for oil main performance indicators:

ISO viscosity classification: VG 32

Viscosity (40 ℃) : 32.2

Viscosity (100 ℃) : 5.61

Viscosity index (D2270) : 113

Density (15 ℃) : 0.8645 g/M3

Flash point: 257 ℃

57 ℃ pour point: -

Emulsification trend (D1401) : 40/40/0 (20 minutes)

Performance characteristics:

High stability, anti-oxidation, run up to 8000-10000 hours;

High security, high flash point 257 ℃;

Synthetic rubber compatibility, outstanding;

, the inherent high viscosity index, shear stability;

Weak, volatile;

Thermal conductivity, excellent;

, the hydrolysis stability of the high - gas and liquid separation effect is good;

, strong dirt and focal scale formation;

To dissolve the existing oil dirties, automatic cleaning the old compressor oil;

(9) with low noise design

Heavy duty design,

, straight driving, no gear noise

Large diameter rotor, low speed (1485 RPM)

, low speed, frequency centrifugal fan;

High efficiency in hot water cooler

Air intake muffler, shell; The compressor inlet noise elimination

Precision sheet metal outer shield